Slipway winches play a crucial role in the maritime industry, facilitating the smooth launching and hauling of vessels. These powerful machines are essential for ensuring the safe and efficient movement of boats and ships in and out of the water. In this article, we will delve into the workings of slipway winches, exploring their mechanisms and the intricate processes involved in launching and hauling vessels.

Understanding Slipway Winches:

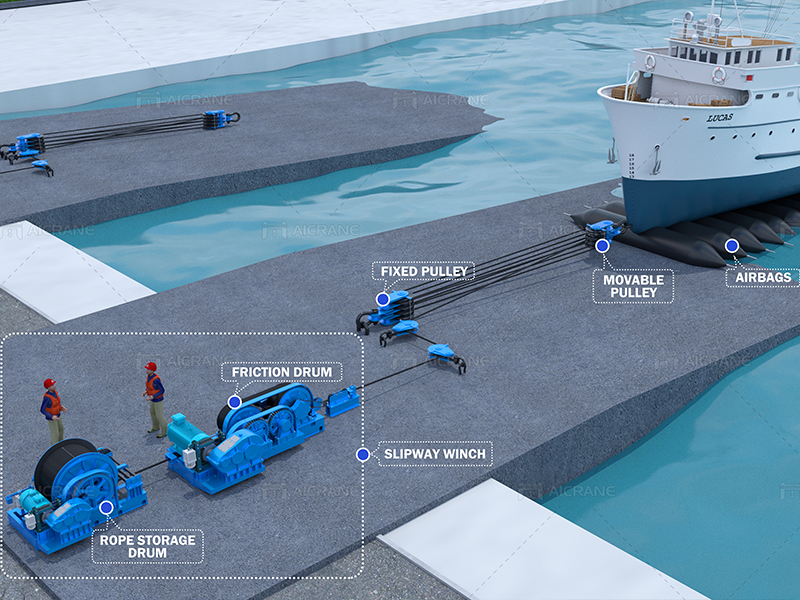

A slipway winch is a mechanical device designed to move vessels along a slipway—a structure typically used for the construction, repair, and maintenance of boats. The slipway winch serves as the powerhouse behind the controlled movement of vessels on and off the slipway. It consists of several key components that work in tandem to execute precise and controlled maneuvers.

Components of a Slipway Winch:

Drum: At the heart of the slipway winch is the drum. The drum is a cylindrical spool around which the hauling cable is wound. It is the primary component responsible for storing and releasing the cable during the launching and hauling processes.

Hauling Cable: The hauling cable, often made of high-strength materials such as steel, is attached to the vessel being moved. This cable is wound and unwound from the drum, dictating the movement of the vessel along the slipway.

Motor and Power System: Slipway winches are equipped with powerful motors that drive the rotation of the drum. The power system provides the necessary force to move the cable and, consequently, the vessel. The energy-efficient and robust nature of these motors ensures reliable performance.

Braking System: A reliable braking system is crucial for maintaining control and preventing unintended movements. The brake engages when the winch is stationary, preventing the drum from unwinding and keeping the vessel securely in place.

Launching Process:

The launching of a vessel using a slipway winch in shipyard involves a systematic and controlled sequence of actions. Here’s an overview of the process:

Preparation: Before launching, the vessel is securely positioned on the slipway. The hauling cable is attached to the vessel’s hull, ensuring a stable connection.

Tensioning the Cable: The winch operator starts the motor, causing the drum to rotate and tension the hauling cable. This tension is carefully regulated to prevent sudden movements and ensure a controlled descent of the vessel into the water.

Release and Descent: With the cable properly tensioned, the brake is released, allowing the drum to unwind. The vessel smoothly descends along the slipway and enters the water.

Hauling Process:

Hauling a vessel out of the water follows a similar process, but in reverse:

Attachment of Cable: The hauling cable is securely attached to the vessel needing to be hauled out of the water.

Tensioning the Cable: The winch operator activates the motor, tensioning the cable and preparing for the hauling process.

Hauling Out: By winding the cable back onto the drum, the winch pulls the vessel out of the water and positions it safely on the slipway.

Safety Considerations:

Launching and hauling vessels using slipway winches require strict adherence to safety protocols. Operators must be well-trained, and winch systems should undergo regular maintenance to ensure optimal performance. Emergency braking systems and fail-safes are often integrated to mitigate potential risks.

Conclusion:

In the maritime industry, slipway winches serve as indispensable tools for the controlled movement of vessels during launching and hauling processes. Their robust design, incorporating drums, cables, motors, and braking systems, ensures the safe and efficient handling of boats and ships. Understanding the mechanics behind slipway winches provides valuable insight into the intricacies of maritime operations, emphasizing the importance of precision and safety in vessel handling. For more info, visit https://steelmillcranes.com/